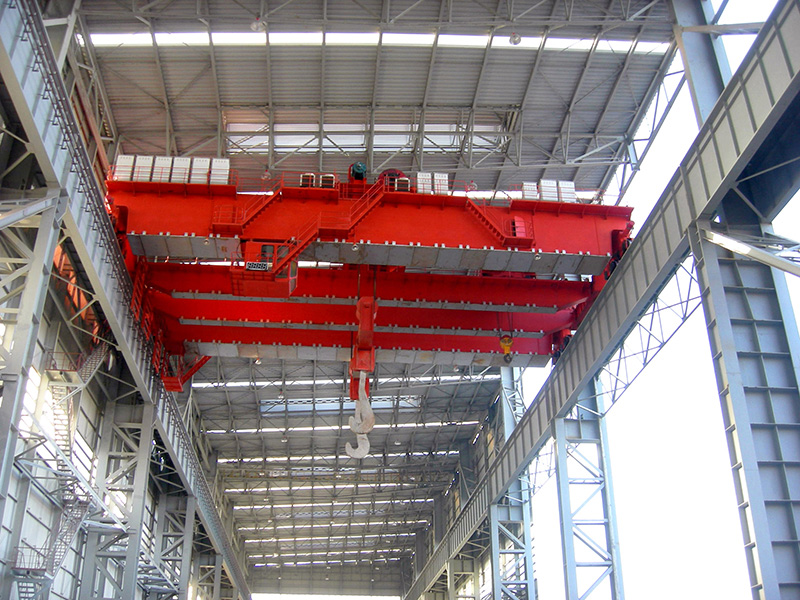

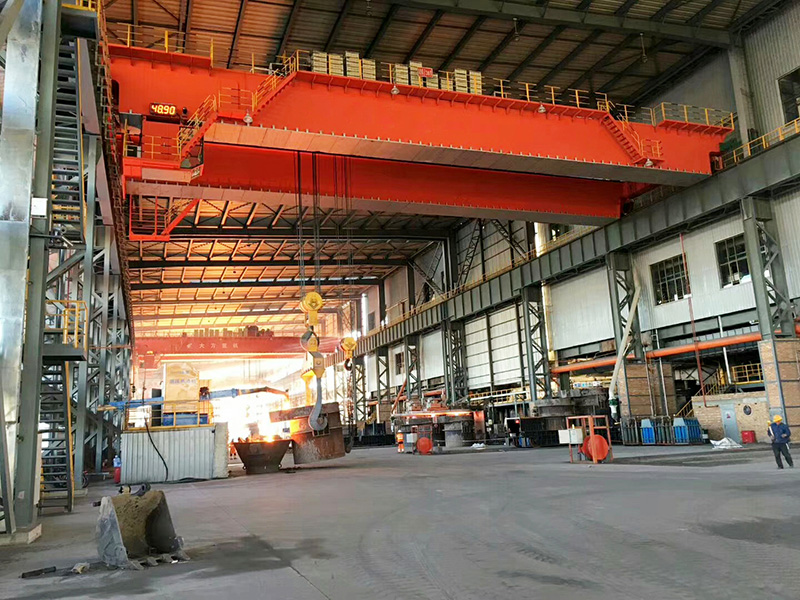

Steel mill cranes are essential pieces of equipment in the steel manufacturing industry. They are specifically designed to handle the rigorous demands and extreme conditions found in steel mills. These cranes play a vital role in various operations, including the transportation of raw materials, the handling of molten metal, and the movement of finished products. Given the harsh environments in which they operate, steel mill cranes must possess certain key features and adhere to stringent safety measures to ensure efficient and safe operation.

Key Features of Steel Mill Cranes

- High Load Capacity: Steel mill cranes are designed to handle extremely heavy loads. They can lift and transport large quantities of raw materials like iron ore, coal, and limestone, as well as massive molten metal containers and finished steel products. The high load capacity is achieved through robust construction, using high-strength materials and advanced engineering techniques.

- Heat Resistance: One of the primary challenges in a steel mill environment is the extreme heat generated during the metal production process. Steel mill cranes are constructed using materials that can withstand high temperatures. Additionally, they are often equipped with heat shields and cooling systems to protect the crane components and ensure reliable operation even in the hottest areas of the mill.

- Durability and Longevity: The constant exposure to harsh conditions, such as heat, dust, and heavy loads, requires that steel mill cranes be exceptionally durable. They are built with high-quality components and materials that resist wear and tear. Regular maintenance and the use of advanced technologies, such as automated lubrication systems, help extend the lifespan of these cranes.

- Precision Control: Precision is critical in steel mill operations, where the accurate positioning of materials and products is necessary to ensure quality and efficiency. Steel mill cranes are equipped with advanced control systems that allow for precise movements and positioning. Features such as variable speed control, anti-sway technology, and automated positioning systems enhance the crane’s accuracy and reliability.

- Automation and Smart Technology: Modern steel mill cranes incorporate advanced automation and smart technologies to improve efficiency and safety. Automated systems can perform repetitive tasks with high precision, reducing the need for manual intervention. Smart sensors and monitoring systems provide real-time data on the crane’s performance and condition, enabling predictive maintenance and minimizing downtime.

- Environmental Protection: Steel mill ladle cranes are often designed with environmental considerations in mind. Features such as energy-efficient motors, regenerative braking systems, and low-emission engines help reduce the environmental impact of crane operations. Additionally, dust suppression systems and enclosed cabins for operators contribute to a cleaner and safer working environment.

Safety Measures for Steel Mill Cranes

- Regular Inspections and Maintenance: Regular inspections and maintenance are crucial to ensure the safe operation of steel mill cranes. This includes routine checks of all crane components, such as hoists, trolleys, cables, and brakes. Maintenance schedules should be strictly followed, and any worn or damaged parts should be replaced immediately to prevent accidents.

- Operator Training and Certification: Operators of steel mill cranes must be thoroughly trained and certified. They should have a deep understanding of the crane’s features, controls, and safety protocols. Ongoing training programs should be provided to keep operators updated on the latest safety practices and technological advancements.

- Safety Systems and Devices: Steel mill cranes are equipped with various safety systems and devices to prevent accidents. These include load limiters, which prevent the crane from lifting loads beyond its capacity, and anti-collision systems, which avoid collisions with other cranes or structures. Emergency stop buttons and automatic shutdown systems provide immediate response in case of malfunction or emergency.

- Fire and Heat Protection: Given the high temperatures in steel mills, cranes must be equipped with fire-resistant materials and heat protection systems. This includes fireproof cables, heat shields, and cooling systems. Additionally, cranes should have fire suppression systems to quickly extinguish any fires that may occur.

- Stability and Anti-Sway Mechanisms: Stability is crucial for the safe operation of steel mill cranes. Anti-sway mechanisms help stabilize the load during lifting and transport, reducing the risk of accidents. These mechanisms use sensors and control algorithms to counteract the swinging motion of the load, ensuring smooth and stable movements.

- Safe Working Load Indicators: Cranes should be equipped with safe working load (SWL) indicators that provide real-time information about the weight of the load being lifted. This helps operators avoid overloading the overhead crane, which can lead to mechanical failure or accidents. Clear markings and audible alarms alert operators when the load exceeds safe limits.

- Personal Protective Equipment (PPE): Operators and workers in the vicinity of steel mill cranes must wear appropriate personal protective equipment (PPE). This includes helmets, gloves, safety goggles, and flame-resistant clothing. PPE helps protect workers from potential hazards such as falling objects, heat, and sparks.

- Emergency Preparedness: Steel mills should have comprehensive emergency preparedness plans in place. This includes regular emergency drills, clearly marked emergency exits, and readily accessible fire extinguishers and first aid kits. Operators and workers should be trained to respond quickly and effectively in case of an emergency.

- Communication Systems: Effective communication is essential for the safe operation of steel mill cranes. Radio communication systems allow operators to stay in constant contact with other workers and supervisors. Clear communication helps coordinate crane movements and ensures that everyone is aware of potential hazards and safety protocols.

- Compliance with Standards and Regulations: Steel mill cranes must comply with national and international safety standards and regulations. Regular audits and inspections by regulatory authorities ensure that cranes meet the required safety standards. Compliance with these regulations helps prevent accidents and ensures a safe working environment.

Conclusion

Steel mill cranes are critical components of the steel manufacturing process, designed to handle extreme conditions and heavy loads. Their key features, such as high load capacity, heat resistance, and precision control, enable them to perform efficiently in demanding environments. Adhering to strict safety measures, including regular maintenance, operator training, and the use of advanced safety systems, is essential to ensure the safe operation of these cranes. By prioritizing safety and incorporating advanced technologies, steel mills can enhance productivity and protect the well-being of their workers. For more information, visit https://steelmillcranes.com/