When it comes to building and construction projects, one of the most commonly used types of bricks is fly ash bricks. Such bricks are compressed at pressures exceeding 272 atmospheres before being placed in a steam bath for curing. The manufacturing process of fly ash bricks ensures that they can withstand hundreds of freeze-thaw cycles. Due to the fact that fly ash bricks are comprised of a large percentage of calcium oxide, the bricks have been known to be called “self-cementing” units by some people.

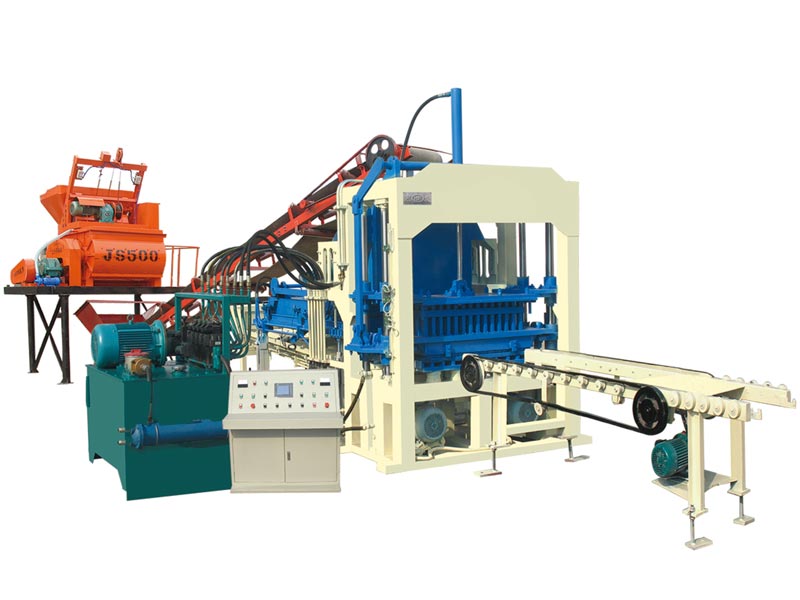

With a semi/fully automatic fly ash brick making machine the process of manufacturing fly ash bricks can be sped up quite considerably. It’s important to note that the cost of manufacturing fly ash bricks is typically 20% lower than the cost of manufacturing traditional clay bricks. What’s more, the manufacturing process produces much less mercury pollution, making it better for the environment.

Raw Materials For Fly Ash Bricks

A typical fly ash brick is comprised of 30% sand, 10% Portland cement, and 60% fly ash. All of the raw materials are combined together with water. Depending on the specifications of the buyer, brick manufacturers can alter formulations and add various additive agents to change the characteristics of the finished bricks. For example, coloring agents can be added to make bright-colored bricks for bespoke building projects.

Manufacturing Fly Ash Bricks

In the past, all types of construction bricks were made by hand. Later, manual brick making presses helped to speed up the traditional method of brick making. Nowadays, manufacturers have access to automatic fly ash brick making machines, which can output thousands of perfectly formed bricks every hour. For mass-scale production, an automatic block making machine is essential. The best thing about semi otomatis harga mesin batu bata fly ash and fully automatic block machine is that they don’t require a large manual workforce for operation. Furthermore, all of the bricks produced are completely symmetrical, which makes for faster completion of construction projects.

Properties Of Fly Ash Bricks

There are a lot of beneficial properties of fly ash bricks that make them such a frequently used brick in the construction industry. To start with, they are very durable, which means they don’t often suffer breakage during transportation. Next, they are highly fire retardant, so they are great for use in the construction of fire-proof walls. A further benefit of fly ash bricks is their lightweight nature – since the bricks are less heavier than other common building blocks, less dead load is placed on supporting structures in construction projects. Furthermore, the bricks have great water resistance properties.

Fly Ash Brick Making Machine Suppliers

You can find dozens of fly ash block making machines for sale on the web. When it comes to choosing a supplier, however, it’s important to research their reputation in the industry. In general, it is best to purchase a block making machine from a leading global brand name like Aimix Group or other semi automatic fly ash brick making machine manufacturers. That way, you can rest assured that you will receive a high-quality piece of machinery that has a long life span and reliable performance.