Rock crushers are indispensable tools for construction and mining projects, making the task of crushing large materials into smaller ones more manageable and efficient. Understanding the various types of rock crushers and their specific applications is crucial for optimizing productivity and minimizing costs within a rock crusher plant. Let’s delve into the key types of rock crushers and discern when to utilize them effectively.

Primary Rock Crushers

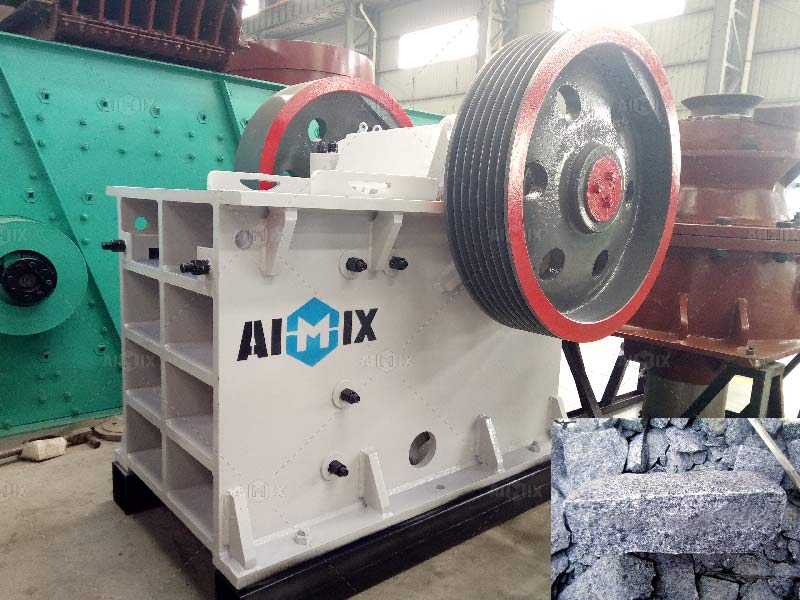

Rock Crusher

The primary rock crusher is typically the first step in the process of reducing large rocks into more manageable sizes. Rock crusher equipment is engineered to handle a variety of materials, including limestone, and is typically used in the construction and demolition industry. Its robust design allows it to withstand the intense pressure and wear that occurs during crushing operations.

Stone Crusher Machine

This type of rock crusher is renowned for its ability to process hard and abrasive materials, making it ideal for the mining industry. A stone crusher machine(Una maquina trituradora de piedra) is designed to break large rocks into a more manageable size, allowing for efficient transportation and further processing.

Secondary Rock Crushers

Limestone Crusher

Designed specifically to handle limestone, this crusher is essential for limestone-rich construction projects and quarries. A limestone crusher is capable of breaking down the rock into various sizes, depending on the requirement, making it a versatile tool for the construction industry.

Tertiary Rock Crushers

Tertiary rock crushers are typically used to produce finely crushed materials and sand, essential for various construction and landscaping projects. They play a critical role in shaping the final product, ensuring its suitability for specific applications. These crushers are often utilized in the production of concrete and asphalt mixes, as well as in the mining industry for ore refinement find more here: https://aimixtrituradora.com/maquina-trituradora-de-rocas.

When to Use Each Type

- Rock crushers are best employed when dealing with large stones and materials with high hardness. They excel at breaking down tough materials efficiently and reliably.

- A rock crusher plant integrating different types of crushers can efficiently process various materials, optimizing the overall crushing process and enhancing productivity.

- Limestone crushers(Trituradoras de caliza) are specifically designed to handle limestone and can be used in various construction projects involving this material.

- Stone crusher machines are best utilized in the mining industry, where they are capable of efficiently breaking down hard and abrasive rocks, facilitating further processing and transportation.